Choosing a clay …

Before the 20 century, the choice of clay was simple – you used whatever was at hand, whatever clay was within cart’s journey of your pottery. For most potters this often meant using the same clay deposit that their father and grandfather and great-grandfather used. At the end of the eighteenth century, some of the larger potteries, such as those in Stoke-on-Trent or Meissen developed their own special clay bodies from a variety of different raw materials, but the craft potter still dug their own from old river beds and other similar deposits.

These days we are lucky to have available to us many many wonderful clay bodies, but even so potters tend to choose one sometimes two and stick with them for years. One of the reasons for this is keeping everything separate is both hard and annoying. Working with porcelain side by side with an iron rich clay body like terracotta would be a nightmare. Even if you are using porcelain and a white stoneware, you need to keep them separate, since they will have different shrinkage rates (think handles cracking off mugs) as well as a number of other problems. So, for the most part potters stick to one clay at a time.

However every so often potters get tchy feet (or perhaps that should be hands), and decide that they’re just not happy with the clay that they’ve been using for the past 5 (or 10 or 20 years). This generally means the start of a huge long cycle where they try 50lbs of every clay in sight before they settle on one. The really crazy ones (err … I mean dedicated ones) decide that what they really have to do is make up their own body with precisely the recipe they want. The well known potters will collaborate with a pottery supply company to make up their ideal clay. The company will then sell that clay under their name. Kind of like Gibson and famous guitarists.

As you might have guessed by now, I got those itchy hands about 6 months ago. The clay I was using, Highwater’s Phoenix, suddenly seemed bland and boring. It’s a pretty generic white stoneware, easy to throw, but not terribly white, nor interestingly speckly. In addition it has a fair bit of mullite grog in it, althought Highwater describes this as “fine” it does leave a fairly rough surface on the bottoms of mugs and so on. In addition it did not have as much wet strength as I would have liked. Essentially any straight sided cylinders over about 13” would start to bulge at the bottom. As you can probably tell I was a bit fed up. So I started looking around at the different clays.

Initially I thought I would just hop over to Highwater’s Moon White, which has very fine Kyanite added to it, which makes it great for large forms, but even at Cone 10 it has an absorbency of 2.3%. This means that it is not particularly vitrified which can leas to overheating in the microwave and other problems.

I spent quite a bit of time researching different bodies online and trying to figure out what sort of pots I wanted to make. Eventually I realised that the clays I was gravitating towards where the ultra-white stonewares, and that in reality many of these are porcelain wanna-bes, formulated for slightly better throwing.

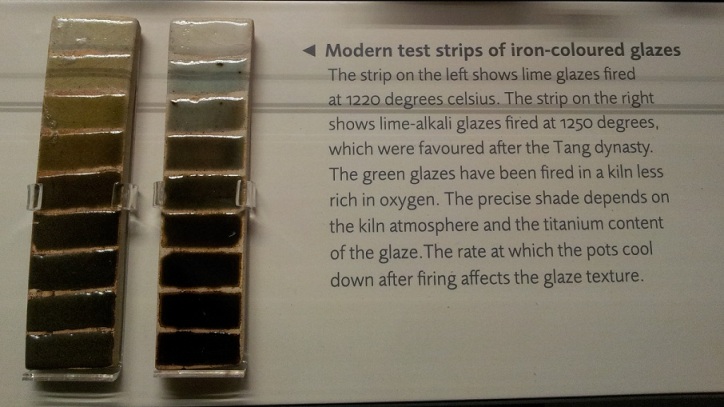

There are a number of good reasons to choose a true porcelain body, not least of which is its translucency and ability to bring a depth to transparent glazes. However, having said that, the high titanium kaolins used in US domestic porcelains render this translucency almost negligible. Unless one is contemplating doing intricate and colourful decoration where an absolutely white background is a must, there seems to be little point in choosing a high titanium porcelain over a good white stoneware.

There are a number of commercially prepared porcelains that use Grolleg, a low titanium Kaolin (or China Clay as we call it over the pond), from Cornwall, or other low titanium clays from New Zealand, so it was to these I turned my attention.

Probably the best source for online opinions on everything from the state of art education to the best style of lids (to pick a couple of recent topics), is the Clayart listserv, whose archives are based at “potters.org”. Browsing through these archives gave me two leads on great grolleg porcelains. One developed by Tom Coleman is manufactured by Aardvark Clay (and sold through many local distributors), and Tom Turner’s Porcelain sold by Standard Clay. I tried 50lbs of both of these, and Laguna/Miller’s “Frost”.

Although Turner’s porcelain was by far the most translucent, with the exposed areas of clay turning that almost glossy white, it was also the most problematic. Almost all pieces showed plucking – that is small pieces of the base getting stuck to the kiln shelves, which leaves characteristic bites out of the footring. I tried a number of solutions to remedy this – for example coating the footring with a mixture of wax and alumina hydrate – but still did not cure it with the few things I tried. Although I did not make any lidded objects, I would have thought those would also have a problem with sticking together. Hardly surprisingly, considering it’s glassy surface (indicating firing very near its limit) it also showed a tendency to warp and slump slightly.

Coleman Porcelain, was also very translucent, but was slightly less white (in oxidation), and examination of the bare ares showed it wasslightly more refractory. Since Tom Turner has developed his body to be fired in oxidation at Cone 9, while Tom Coleman fires to Cone 10 (or higher) in reduction, these differences are not surprising.

The Laguna/Miller frost, was even less translucent than the Coleman Porcelain, and threw less thinly I did not consider it any further. (On the other hand it is significantly cheaper than either of the other two, and handles have less of a tendency to crack off).

In terms of throwing both the Turner and Coleman Porcelain threw extremely well – in fact I could not detect any more difficulty in throwing it than I did Phoenix. With both of them I could easily throw cylinders more than 12 inches in height from 2kg (4.4 lbs) of clay. I would say that the Coleman porcelain feels more pastic, but the Turner porcelain is more solid and has more tooth. I would say that it throws marginally taller too (maybe 13+ inches versus 12 1/2?). Certainly either of them would be great choices for a porcelain. In the end my choice came down to convenience – Turner porcelain is significantly more difficult for me to get hold of since there are no local distrbutors. It’s also somewhat more expensive, but when you sell mugs for $20-25 it hardly makes a difference. Having used Coleman porcelain solidly for a few months I will say that there are a few problems. Most significantly is that it is significantly less tolerant of differences in wetness when attaching handles. After handles are attached, the mugs MUST be dried very very slowly (4 days or more). When space is at a premum in a small studio, this is very irritating.

The only problem with changing to a porcelain clay? My glazes didn’t work properly anymore. Or rather they looked totally different on the porcelain. And the Mossy Mahogany particularly seemed to run more than usual. In addition, I really wanted to develop more translucent glazes to take advantage of porcelain’s particular properties. I’ve therefore spent the last 6 months or so mostly working on expanding my pallette of glazes.

I’m aiming to bring you a lot more pictures of my glaze tests in future blog posts.

From Left to Right : Coleman Porcelain, Turner Porcelan, Phoenix Stoneware

All with Mossy Mahogany glaze.